The Importance of Efficient Warehouse Management

In today’s fast-paced retail landscape, efficient warehouse management is crucial for businesses to maintain a competitive edge. Traditional approaches to warehouse operations often rely on manual processes and outdated systems, leading to numerous challenges such as inventory inaccuracies, inefficient picking and packing, and excessive labor costs.

These inefficiencies can have far-reaching consequences throughout the supply chain, resulting in stockouts, delayed shipments, and ultimately, dissatisfied customers. In an era where consumer expectations for fast and reliable delivery are higher than ever, such shortcomings can severely impact a business’s reputation and bottom line.

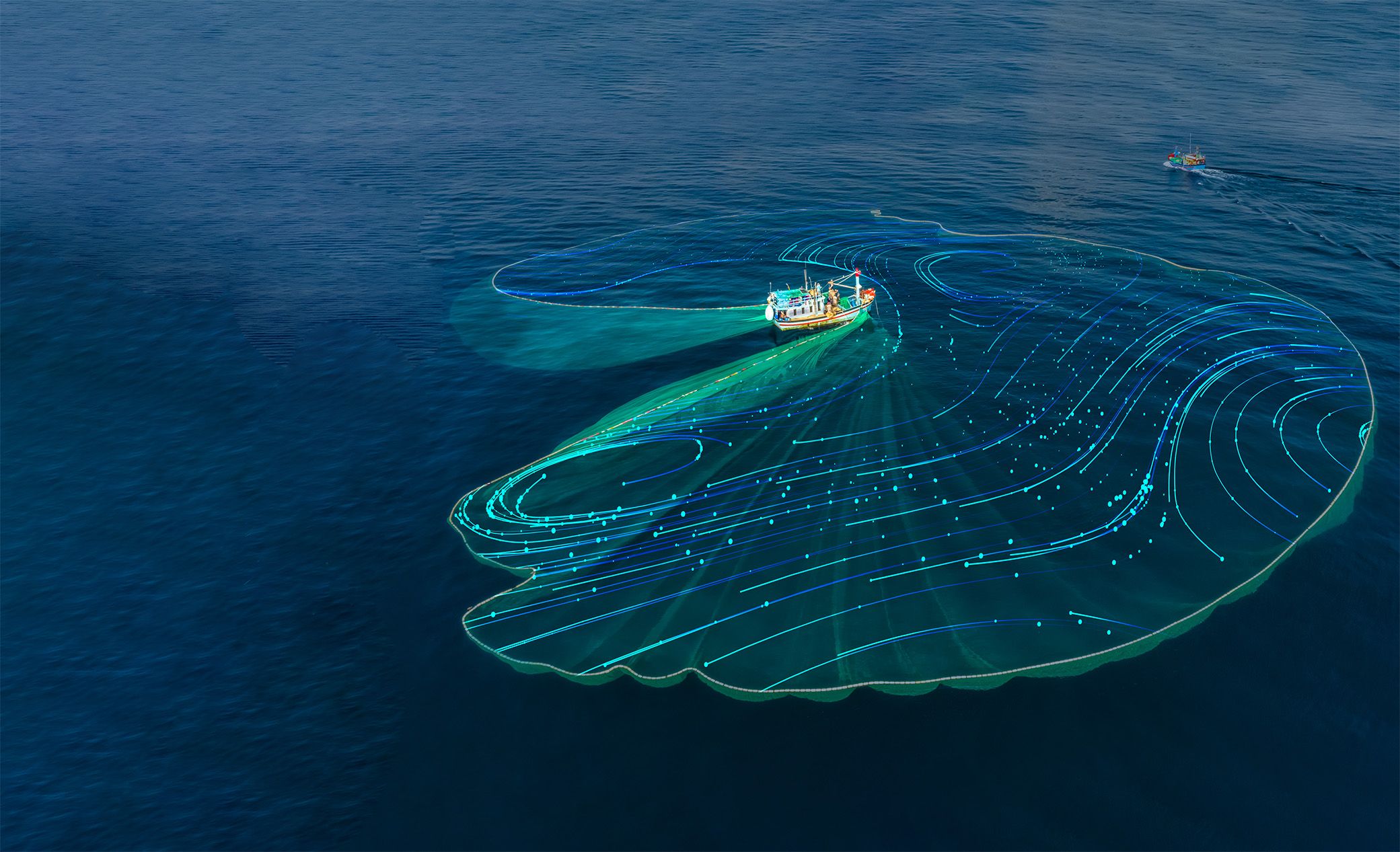

To address these challenges, modern retailers are turning to innovative solutions that leverage cutting-edge technologies like artificial intelligence (AI) and integrated enterprise systems. By embracing these advanced tools, companies can streamline their warehouse operations, optimize inventory management, and enhance overall supply chain efficiency, ultimately delivering superior customer experiences and driving business growth.

AI for Inventory Tracking and Management

Artificial Intelligence (AI) is revolutionizing inventory tracking and management in warehouses, enabling unprecedented levels of efficiency and accuracy. AI-powered inventory tracking systems leverage computer vision, machine learning, and advanced analytics to automate stock level monitoring, reduce human error, and optimize inventory levels.

One of the key advantages of AI in inventory management is automated stock level monitoring. Intelligent cameras and sensors can continuously scan warehouse shelves, bins, and racks, providing real-time updates on stock levels for each item. This eliminates the need for manual counting, which is time-consuming, error-prone, and often incomplete due to human limitations.

Moreover, AI-driven predictive analytics plays a crucial role in demand forecasting. By analyzing historical sales data, market trends, customer behavior, and external factors, AI algorithms can accurately forecast future demand for various products. This allows warehouses to maintain optimal inventory levels, reducing the risk of overstocking or stockouts, and ensuring timely replenishment.

AI systems can also detect patterns and anomalies in inventory data, alerting managers to potential issues such as theft, misplacement, or damage. This proactive approach helps mitigate losses and maintain inventory integrity, ultimately leading to cost savings and improved operational efficiency.

Benefits of AI in Warehouse Operations

Implementing AI in warehouse operations offers numerous advantages that can significantly optimize processes and drive cost savings. One of the primary benefits is increased accuracy in tasks such as inventory tracking, order fulfillment, and stock management. AI algorithms can precisely monitor stock levels, identify discrepancies, and ensure the right products are picked and packed for each order, minimizing errors and enhancing customer satisfaction.

Moreover, AI solutions can reduce labor costs by automating repetitive and time-consuming tasks, freeing up human workers to focus on more complex and value-adding activities. Intelligent robots and autonomous systems can handle material handling, sorting, and transportation, operating around the clock with minimal supervision and reducing the need for manual labor.

Efficient space utilization is another advantage of AI in warehouse management. AI-powered algorithms can analyze data on product demand, inventory levels, and warehouse layout to optimize space allocation and storage strategies. This can lead to better organization, reduced clutter, and maximized use of available space, ultimately increasing storage capacity without the need for physical expansion.

Additionally, AI can help minimize waste and losses in warehouse operations. By accurately tracking inventory levels and expiration dates, AI systems can alert managers to potential overstocking or expired products, enabling timely actions to prevent waste. Furthermore, AI can identify and mitigate potential sources of product damage or loss, such as environmental factors or mishandling, leading to reduced losses and improved cost-effectiveness.

Integrated Warehouse Management Systems

Integrated warehouse management systems (WMS) offer a centralized platform for managing and optimizing all aspects of warehouse operations. By consolidating data and processes, these enterprise solutions provide real-time visibility and control over inventory, personnel, and resources. This level of integration streamlines workflows, eliminates silos, and ensures seamless coordination across the entire supply chain.

One of the key advantages of an integrated WMS is the ability to centrally manage data and processes. With a single source of truth, businesses can access accurate, up-to-date information on inventory levels, order statuses, and resource allocation. This centralized approach eliminates the need for manual data entry and reconciliation, reducing errors and increasing efficiency.

Real-time visibility and control are critical in today’s fast-paced business environment. Integrated WMS solutions provide a comprehensive view of warehouse operations, enabling managers to monitor performance, identify bottlenecks, and make informed decisions. This level of visibility extends beyond the warehouse walls, allowing for seamless coordination with suppliers, carriers, and customers.

By streamlining workflows, integrated WMS solutions optimize processes and eliminate redundancies. Automated task assignment, route optimization, and real-time updates ensure that resources are utilized effectively, reducing waste and improving productivity. These streamlined workflows also enhance accuracy and consistency, minimizing the risk of errors and improving customer satisfaction.

As businesses grow and expand their operations, scalability becomes a critical factor. Integrated WMS solutions are designed to accommodate growth, allowing for seamless integration with new facilities, technologies, and processes. This scalability ensures that businesses can adapt to changing market conditions and customer demands without compromising efficiency or productivity.

Improving Picking and Packing Efficiency

AI and enterprise solutions have revolutionized the picking and packing processes within warehouses, leading to significant improvements in efficiency, accuracy, and productivity. One of the key areas where AI shines is automated order processing. By integrating AI-powered systems, warehouses can streamline the entire order fulfillment cycle, from receiving customer orders to dispatching shipments.

AI algorithms can analyze order data, inventory levels, and historical trends to optimize pick paths and routes, ensuring that pickers follow the most efficient routes throughout the warehouse. This minimizes travel time and maximizes productivity, resulting in faster order processing and reduced labor costs.

Vision systems powered by AI play a crucial role in quality checks during the picking and packing stages. These systems can automatically identify and flag damaged or incorrect items, reducing the risk of shipping errors and ensuring that customers receive their orders in perfect condition.

Packing automation is another area where AI excels. AI-driven robotic systems can efficiently pack orders, ensuring optimal use of packaging materials and minimizing waste. These systems can also handle complex packing requirements, such as fragile or irregularly shaped items, with precision and care.

By leveraging AI and enterprise solutions, warehouses can streamline their picking and packing operations, resulting in faster order fulfillment, improved accuracy, and enhanced customer satisfaction.

AI for Autonomous Logistics and Material Handling

One of the most transformative applications of AI in warehouse operations is autonomous logistics and material handling. This encompasses a range of cutting-edge technologies, including self-driving vehicles and robots, automated storage and retrieval systems, and AI-powered routing and scheduling.

Self-driving vehicles and robots are revolutionizing the way goods are transported within warehouses. These autonomous systems can navigate complex environments, avoiding obstacles and optimizing routes for maximum efficiency. They can be programmed to follow predefined paths or dynamically adjust their movements based on real-time data, ensuring seamless coordination and minimizing bottlenecks.

Automated storage and retrieval systems (AS/RS) are another game-changer in warehouse operations. These systems use AI algorithms to optimize the storage and retrieval of goods, reducing the need for manual intervention and increasing accuracy. By analyzing data on inventory levels, demand patterns, and warehouse layouts, AI can determine the most efficient storage locations and retrieval sequences, minimizing travel distances and maximizing throughput.

AI-powered routing and scheduling systems take warehouse optimization to the next level. These systems leverage machine learning algorithms to analyze vast amounts of data, including order volumes, resource availability, and operational constraints, to generate optimized schedules and routes for material handling equipment and personnel. This not only improves efficiency but also reduces costs associated with labor, energy consumption, and equipment maintenance.

Overall, AI-driven autonomous logistics and material handling solutions are transforming warehouses into highly efficient, data-driven operations, enabling businesses to meet the ever-increasing demands of modern supply chains while reducing operational costs and improving customer satisfaction.

Use Cases

Numerous companies across various industries have successfully leveraged AI to improve their warehouse operations, resulting in substantial improvements in efficiency, productivity, and cost savings. Let’s explore some use cases that showcase the power of AI in warehouse management.

Retail Giant Optimizes Inventory Management

A leading retail company with a vast network of distribution centers faced challenges in accurately tracking and managing its vast inventory. By implementing an AI-driven inventory management system, they achieved real-time visibility into stock levels, enabling proactive replenishment and reducing out-of-stock situations by 25%. Additionally, the system’s predictive analytics capabilities helped optimize inventory levels, resulting in a 15% reduction in carrying costs.

Automotive Manufacturer Enhances Picking Accuracy

In the fast-paced automotive industry, a major manufacturer struggled with picking errors, leading to delays and customer dissatisfaction. They deployed an AI-powered picking solution that utilized computer vision and machine learning algorithms to verify each pick, significantly reducing errors by 95%. This not only improved customer satisfaction but also minimized costly returns and rework.

E-Commerce Giant Streamlines Fulfillment Operations

An e-commerce giant faced the challenge of efficiently processing millions of orders daily across multiple fulfillment centers. By integrating AI-driven robotics and automation, they optimized their picking, packing, and sorting processes, resulting in a 30% increase in throughput and a 20% reduction in labor costs. Additionally, the AI system’s ability to learn and adapt to changing demand patterns ensured seamless scalability during peak seasons.

Overcoming Challenges: Change Management and Data Quality

While the benefits of AI in warehouse management are undeniable, companies often face challenges in implementing these solutions. One common hurdle is change management, as it requires a cultural shift and buy-in from employees. Effective training and communication strategies are crucial to address concerns and ensure a smooth transition.

Another challenge lies in the quality and availability of data. AI systems rely on accurate and comprehensive data to make informed decisions. Companies must invest in data cleaning, integration, and governance processes to ensure the reliability of their AI solutions.

By addressing these challenges head-on and leveraging the power of AI, companies can unlock unprecedented levels of efficiency, productivity, and cost savings in their warehouse operations, positioning themselves for long-term success in an increasingly competitive landscape.

Overcoming Barriers to AI Adoption

While the benefits of AI-driven warehouse management are compelling, organizations often face challenges in successfully implementing these solutions. Three key barriers that must be addressed are change management and workforce training, data quality and integration, and cybersecurity and privacy concerns.

Change Management and Workforce Training: Introducing AI into warehouse operations can be a significant cultural shift for employees accustomed to traditional processes. Effective change management strategies are crucial to ensure a smooth transition. This includes providing comprehensive training programs to upskill employees on the use of AI-powered systems and addressing any concerns or resistance to the adoption of new technologies. Fostering a culture of continuous learning and embracing innovation can help overcome resistance and ensure successful AI implementation.

Data Quality and Integration: AI systems rely heavily on high-quality, accurate data to function effectively. Many organizations struggle with siloed and inconsistent data sources, which can hinder the performance of AI solutions. Implementing robust data governance practices, ensuring data quality, and seamlessly integrating data from various sources across the supply chain are essential for optimal AI performance. Investing in data cleansing, standardization, and integration efforts is crucial for realizing the full potential of AI in warehouse management.

Cybersecurity and Privacy Concerns: As AI systems become more prevalent in warehouse operations, ensuring the security and privacy of sensitive data becomes paramount. Cybersecurity threats, such as data breaches, malware attacks, and unauthorized access, can compromise the integrity and reliability of AI systems. Organizations must implement robust cybersecurity measures, including encryption, access controls, and regular security audits, to protect their AI infrastructure and safeguard sensitive data. Additionally, adhering to data privacy regulations and ensuring the ethical use of AI technologies is crucial for maintaining consumer trust and compliance.

Choosing the Right AI and Enterprise Solution

Selecting the appropriate AI and enterprise solution is crucial for maximizing the benefits of these technologies in warehouse management. Evaluating technology providers based on their expertise, track record, and industry-specific solutions is essential. Scalability and flexibility are critical factors to consider, as warehouse operations are dynamic and may require adjustments over time.

The chosen solution should seamlessly integrate with existing systems, such as enterprise resource planning (ERP), warehouse management systems (WMS), and transportation management systems (TMS). This integration ensures a streamlined flow of data and eliminates silos, enabling real-time visibility and decision-making across the entire supply chain.

Additionally, implementation and support services play a vital role in the successful adoption of AI and enterprise solutions. Technology providers should offer comprehensive training, deployment assistance, and ongoing support to ensure smooth implementation and optimal performance. Regular software updates, maintenance, and troubleshooting are essential to maintain the system’s efficiency and effectiveness.

By carefully evaluating and selecting the right AI and enterprise solution, organizations can future-proof their warehouse operations, enabling them to adapt to changing market demands, technological advancements, and evolving customer expectations.

The Future of AI in Warehouse Management

The integration of AI in warehouse operations is poised for remarkable growth and innovation in the coming years. As AI technologies continue to evolve, we can expect to see more advanced and sophisticated applications that will transform the way warehouses operate.

One of the most exciting prospects is the emergence of new AI technologies and trends. Machine learning algorithms are becoming increasingly powerful, enabling more accurate forecasting, predictive maintenance, and real-time optimization of warehouse processes. Additionally, the advent of edge computing and 5G networks will enable faster data processing and decision-making, leading to more efficient and responsive warehouse operations.

Another major trend is the increased automation and autonomous operations within warehouses. AI-powered robots and autonomous vehicles are already being used for tasks such as picking, packing, and material handling. In the future, we can expect to see fully autonomous warehouses, where AI systems orchestrate the entire operation with minimal human intervention. This will not only improve efficiency but also enhance safety and reduce the risk of human error.

Sustainability and environmental impact are also becoming increasingly important considerations in warehouse management. AI can play a crucial role in optimizing energy consumption, reducing waste, and minimizing the carbon footprint of warehouse operations. Predictive analytics can be used to optimize routes and schedules, reducing fuel consumption and emissions from transportation. Additionally, AI-powered systems can monitor and control lighting, heating, and cooling systems, ensuring optimal energy efficiency.

Overall, the future of AI in warehouse management promises to be exciting and transformative. As AI technologies continue to evolve and become more accessible, we can expect to see warehouses that are more efficient, sustainable, and responsive to changing demands, ultimately driving greater profitability and competitiveness for businesses.

In today’s fast-paced retail landscape, optimizing warehouse operations is crucial for maintaining a competitive edge. By embracing AI-powered warehouse management solutions, businesses can unlock unprecedented levels of efficiency, streamline processes, and drive substantial cost savings.

One of the primary benefits of AI-driven warehouse management is the ability to accurately forecast demand, ensuring optimal inventory levels and minimizing overstocking or understocking situations. Advanced algorithms can analyze historical data, market trends, and customer behavior patterns, enabling precise inventory planning and reducing carrying costs.

Moreover, AI solutions can revolutionize picking and packing processes, minimizing errors and maximizing productivity. Intelligent systems can optimize route planning, task allocation, and real-time adjustments based on dynamic conditions, resulting in faster order fulfillment and improved customer satisfaction.

Beyond operational efficiencies, AI-powered warehouse management solutions offer a significant competitive advantage. By leveraging cutting-edge technologies, businesses can stay ahead of the curve, adapting to evolving market demands and outpacing competitors who rely on traditional methods.

To experience the transformative power of AI-driven warehouse management firsthand, we invite you to request a personalized demo or consultation. Our experts will guide you through the capabilities of our solutions and tailor them to your specific business needs, ensuring a seamless integration and maximizing your return on investment.

Embrace the future of warehouse operations and unlock unprecedented levels of efficiency, accuracy, and cost savings. Contact us today to schedule your demo and embark on a journey towards AI-driven excellence in warehouse management.