In the dynamic landscape of manufacturing, digital transformation has become a catalyst for change. The profound impact of embracing digital technologies on manufacturing processes, from the shop floor to the supply chain, is reshaping the industry.

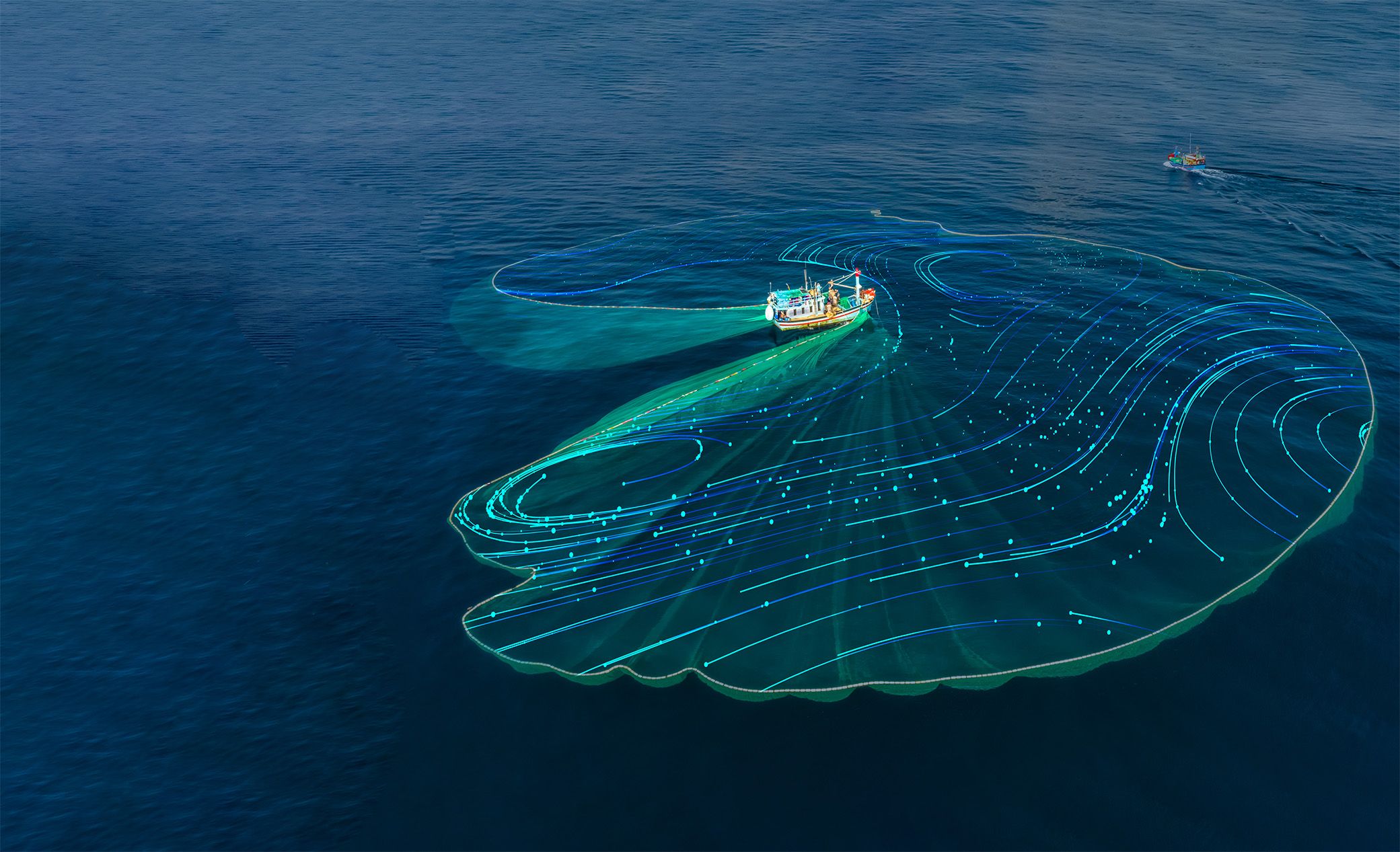

The integration of the Internet of Things (IoT) into manufacturing processes allows for real-time monitoring of machinery and equipment. This connectivity enhances efficiency by providing insights into equipment performance, reducing downtime, and optimizing maintenance schedules.

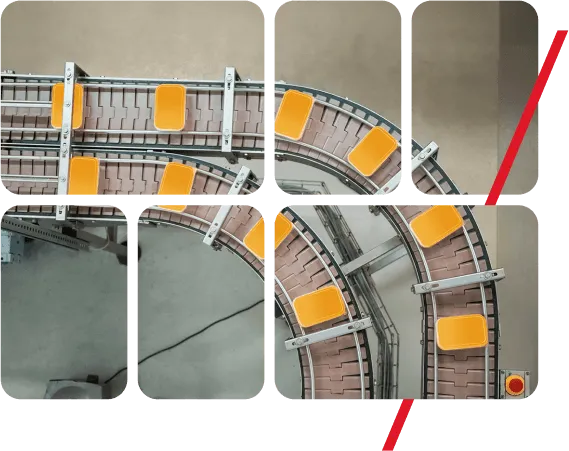

Automation, including robotic process automation (RPA), is revolutionizing manufacturing by streamlining repetitive tasks, improving precision, and increasing overall production speed. The implementation of automation technologies leads to enhanced operational efficiency and resource utilization.

The power of data analytics in manufacturing cannot be overstated. From predictive maintenance to quality control and demand forecasting, data-driven insights empower manufacturers to make informed and strategic decisions. Harnessing the potential of big data transforms challenges into opportunities.

Digital twins, or virtual replicas of physical systems, enable simulations, testing, and optimization before actual production. This innovation reduces risks, fosters creativity, and allows manufacturers to fine-tune processes for maximum efficiency. The era of digital twins is unlocking new possibilities for innovation in manufacturing.

While the benefits are significant, implementing digital transformation in manufacturing comes with challenges such as cybersecurity concerns and the need for workforce adaptation. Looking ahead, the industry is poised for further advancements, including the integration of artificial intelligence (AI) and blockchain, marking the next phase of manufacturing evolution.

The journey of digital transformation in manufacturing is a pathway to unlocking unprecedented efficiency and fostering innovation. Embracing these technologies positions manufacturers not only to meet current demands but also to thrive in an ever-evolving industry.

- industries

- / industries

- retail

-

/ retail

In the intricate world of retail, mindit.io stands out as your strategic ally.

-

- banking

- / banking

In the intricate world of retail, mindit.io stands out as your strategic ally.

-

- financial services

-

/ financial services

In the intricate world of retail, mindit.io stands out as your strategic ally.

-

- healthcare

-

/ healthcare

In the intricate world of retail, mindit.io stands out as your strategic ally.

-

- hospitality

- / hospitality

In the intricate world of retail, mindit.io stands out as your strategic ally.

-

- foodtech

- / foodtech

In the intricate world of retail, mindit.io stands out as your strategic ally.

-

- manufacturing

- / manufacturing

In the intricate world of retail, mindit.io stands out as your strategic ally.

-

- publishing

- / publishing

In the intricate world of retail, mindit.io stands out as your strategic ally.

-

- real estate

- / real estate

In the intricate world of retail, mindit.io stands out as your strategic ally.

-

- telco

- / telco

In the intricate world of retail, mindit.io stands out as your strategic ally.

-

- services

- / services

- enterprise applications

- / enterprise applications

Our enterprise applications integrate seamlessly with your existing systems, providing a unified solution.

Our enterprise applications integrate seamlessly with your existing systems, providing a unified solution.

-

- product engineering

- / product engineering

We specialize in Software Product Engineering, transforming your concepts into impactful products.

We specialize in Software Product Engineering, transforming your concepts into impactful products.

-

- data & analytics

-

/ data & analytics

Data Analytics is where IT, statistics, and business converge.

Data Analytics is where IT, statistics, and business converge.

-

- artificial intelligence

- / artificial intelligence

Artificial intelligence and machine learning: we can unlock business potential through automation within your organization.

Artificial intelligence and machine learning: we can unlock business potential through automation within your organization.

-

- integration solutions

- / integration solutions

Streamline IT projects, reduce risks, and ensure on-time, on-budget technology deployment aligned with your business goals.

Streamline IT projects, reduce risks, and ensure on-time, on-budget technology deployment aligned with your business goals.

-

- maintenance & support

- / maintenance & support

Secure and reliable software performance with proactive issue identification and disaster recovery strategies

Secure and reliable software performance with proactive issue identification and disaster recovery strategies

-

- cloud & infrastructure services

- / cloud & infrastructure services

Achieve more with our tailored DevOps, cloud, and infrastructure services for smooth, efficient, and secure operations.

Achieve more with our tailored DevOps, cloud, and infrastructure services for smooth, efficient, and secure operations.

-

- / accelerators

- / accelerators

Our accelerators are built to drive growth and enhance your organization’s capabilities.

Our accelerators are built to drive growth and enhance your organization’s capabilities.

-

- success stories

- / success stories

- retail

-

/ retail

A global retailer, with 2200 stores & 25,000 employees, had critical issues in its Java legacy web application.

A global retailer, with 2200 stores & 25,000 employees, had critical issues in its Java legacy web application. We facilitated a decision on how much to invest in novelty items for one of the world’s biggest retail players.

We facilitated a decision on how much to invest in novelty items for one of the world’s biggest retail players.

-

- banking

- / banking

Partnered with fin-tech to create an algorithm for tailored investment choices

Partnered with fin-tech to create an algorithm for tailored investment choices Migration to TIBCO BW6: Key European bank tackled complex business logic & integrated components using ESB architecture.

Migration to TIBCO BW6: Key European bank tackled complex business logic & integrated components using ESB architecture.

-

- financial services

- / financial services

Cross-border payment solution for education, healthcare, and businesses worldwide.

Cross-border payment solution for education, healthcare, and businesses worldwide.

-

- healthcare

- / healthcare

Swisscom’s Medical Connector offers DICOM-standard data communication with no size limits for providers.

Swisscom’s Medical Connector offers DICOM-standard data communication with no size limits for providers.

-

- hospitality

- / hospitality

Powertage Chat uses RAG to deliver fast, accurate answers to visitor and exhibitor questions.

Powertage Chat uses RAG to deliver fast, accurate answers to visitor and exhibitor questions. Developed a white-label app for 2023 Rugby World Cup, enhancing UX and expanding client expertise.

Developed a white-label app for 2023 Rugby World Cup, enhancing UX and expanding client expertise.

-

- foodtech

- / foodtech

Planteneers offers a virtual product catalog configuration experience.

Planteneers offers a virtual product catalog configuration experience.

-

- manufacturing

- / manufacturing

We Partnered for production boost, cost reduction, and quality. Our software maximizes efficiency & savings.

We Partnered for production boost, cost reduction, and quality. Our software maximizes efficiency & savings.

-

- publishing

- / publishing

Enhanced Izzard Ink with automated royalties & AI manuscript analysis for improved efficiency.

Enhanced Izzard Ink with automated royalties & AI manuscript analysis for improved efficiency.

-

- real estate

- / real estate

Efficiency in Real Estate: Created a Customer Portal for owners 55+, providing secure equity release info access.

Efficiency in Real Estate: Created a Customer Portal for owners 55+, providing secure equity release info access.

-

- telco

- / telco

Developing Telco Apps for one of the most dynamic telco companies from Romania.

Developing Telco Apps for one of the most dynamic telco companies from Romania.

-

- company

- / company

- about us

-

/ about us

The partner of choice for data & product engineering to drive business growth & deliver an impact within your organization

The partner of choice for data & product engineering to drive business growth & deliver an impact within your organization

-

- product engineering

- / product engineering

We specialize in Software Product Engineering, transforming your concepts into impactful products.

We specialize in Software Product Engineering, transforming your concepts into impactful products.

-

- technology

- / technology

250+ specialists skilled in software, BI, integration, offering end-to-end services from research to ongoing maintenance.

250+ specialists skilled in software, BI, integration, offering end-to-end services from research to ongoing maintenance.

-

- methodology

- / methodology

We specialize in software product engineering, transforming your concepts into impactful products.

We specialize in software product engineering, transforming your concepts into impactful products.

-

- careers

- / careers

Our team needs one more awesome person, like you. Let’s grow together! Why not give it a try?

Our team needs one more awesome person, like you. Let’s grow together! Why not give it a try?

-

- do good

- / do good

We’re a team devoted to making the world better with small acts. We get involved and always stand for kindness.

We’re a team devoted to making the world better with small acts. We get involved and always stand for kindness.

-

- events

- blog

- contact us

- / contact us

We would love to hear from you! We have offices and teams in Romania and Switzerland. How can we make your business thrive?

We would love to hear from you! We have offices and teams in Romania and Switzerland. How can we make your business thrive?

-

- / get in touch